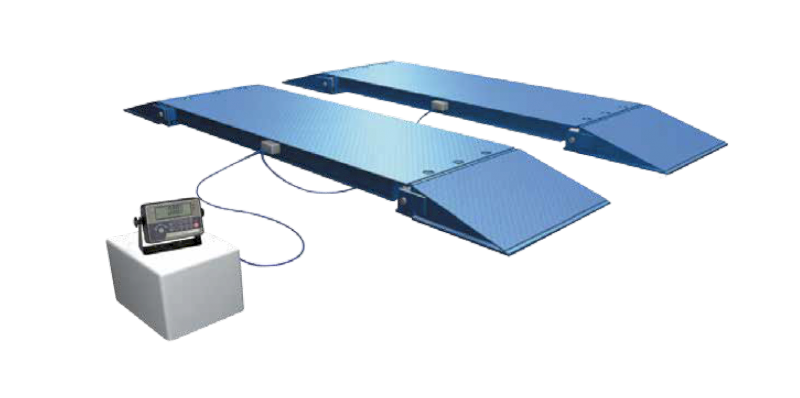

Portable Low Profile Industrial Weighbridges - In Trade Approved & No-Trade Configurations

$0.00 + GST ($0.00 Inc. GST)

Details

| Status | : | Farm Inputs |

| Location | : | Elmore, Central, VIC |

| Category | : | Machinery & Equipment, Weighbridge or Weighing |

| Listing Date | : | 18/10/2021, 03:15pm |

Description

- Low-profile

- High Accuracy & Dependable Total Vehicle Weighing

- No Moving Parts to Wear Out

- Hermecticallly Sealed Load Celss

- Can be used Outdoor & Indoors, Rain or Shine

- Safe for Corrosive & Washdown Application

- Made from 17-4HP tool steel

- Welded header for Protection against Moisture Damage

- Galvanised Heavy-Duty Steel Rust protection in any environment

- Portable Design & User-Friendly Installation

- Pads can be Lifted into Position with a Forklift

- Spare Parts Readily Available

- Can be packed up & relocated cost effectively

Can be customised for your Business - Add ons can increase efficiency and reduce downtime

Weighbridge Add-On Options:

Safety & Traffic Add ons: Security Cameras, Traffic Lights, Guard Rails, Boom Gates

Display Add Ons: Remote Displays, Digital indicators

Remote Management Add Ons: Driver Control Stations so you can run Unmanned Sites

Reporting Add Ons: Truck Fleet management software, Printers, Accounting System Interfacing Software

Quality Control Add Ons: Wireless Link to Front End Loaders, Wheel Washers

Software can be customise to suit your specific requirements:

Account Management

Fleet Management

The Basic Concept: How They Work

1. Trucks wait, for clearance access Weighbridge ramps (either Traffic Lights, Speakers, Large Displays)

2. Once the go ahead is given, the truck travels slowly up the ramps on to the weighbridge deck, stopping when truck is fully on deck (or if axle weighing continue the process until all axle groups are weighed e.g trailer, B-trailer, dog or pig trailers etc.)

3. The bridge has been calibrated to Zero, the load cells detects a change in weight

4. The Load Cell sensing element is designed in such a way it develops a strain, directly proportional to the load applied

5. The strain gauges, are usually connected in multiples of four, called a Wheatstone bridge configuration - converting the very small change in resistance into a usable electrical signal.

6 The electrical signal is converted by the instrumentation, and shows the truck's weigh on the indicators

7. The driver & operator, now knows if the truck complies with Chain of Responsibility Legislation

8. The truck driver can exit via the ramp, once the go ahead is given and it's safe to proceed

9. The truck driver can then proceed on its journey or reload their truck to keep them legal, as well as make sure they're not under loaded or overloaded

10. Continue the weighing process if your truck does not fully fit onto the weighbridge until all axle groups are captured.

Single Deck Weighbridge

• It’s very difficult to get different axle group loadings accurately on a Single Deck Weighbridge, with a single weigh operation.

• The work-around involves making multiple truck movements, so each axle group, is weighed on the single weighbridge deck (called Split weighing).

• This method requires level ground before and after the weighbridge to achieve axleweighs.

• This Split weighing method requires operators knowledge to determine axle group weights and equally time consuming.

Multi Deck Weighbridge

• The Multi Deck Weighbridges are designed to provide an efficient method of weighing different truck axle groups, in a single weigh operation (in most cases).

• The Multi Deck can be designed to suit most truck configurations, to minimise truck repositioning on the weighbridge

• Shows the operators & truck drivers the weights of the different axle groups and displays the total gross weight

• Saves time because the driver can get an accurate reading of each axle groups, without having to keep manoeuvering their truck over the Weighbridge.

Sign in to comment, quote or offer and get seller's contact information.

Sign In or Register for FREE!

Share Listing Via