Combine Harvester Types - Single Rotor

- By: "Farm Tender" News

- Machinery & Equipment News

- Sep 17, 2024

- 1039 views

- Share

By Phil Rowntree - 0428 659 056 - philr@farmtender.com.au

All modern combines have the same task to achieve, and it is one of the most labour-saving inventions of its time: They are designed to

- Cut the crop

- Thresh the crop

- Separate the grain from the heads

- Clean the straw and chaff from the grain

Single Rotor

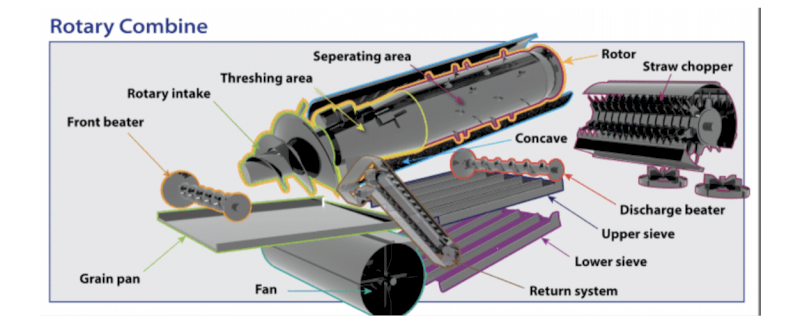

The first single rotor combine was manufactured by International Harvester and have been available since 1977. Today most manufacturers offer a single rotor combine. The single rotor design departed from the traditional conventional combine harvester, in that threshing and separation was performed predominantly by rotor, as opposed to the drum/cylinder and straw walker type models we featured previously.

As with all combines the crop flows in via the feeder housing. At this point it will be handled by an east/west feeding drum or beater depending on manufacturer. This drum, beater generally runs at a lower RPM than the rotor and will assist with the crop entering the rotor. Some separation may be present at this point.

Once the crop has entered the rotor, grain is predominantly removed by centrifugal force rather than gravity in the spinning motion.

The rotor is larger than a conventional cylinder and the crop spins between the rotor and the concave threshing and separating the grain.

Due to the concave gap not generally requiring to be as tight as conventional cylinder, a gentler threshing can be achieved and therefore reduce grain damage.

As per conventional combines the concave gap and rotor RPM can be adjusted to suit conditions. Length and diameter of rotors will give different performance in different conditions. Rotor pitch is also to be considered in performance.

The majority of remaining straw will exit the combine via the rear of the rotor this may pass through a chopper/beater system. Clean grain and chaff etc will fall on to the sieves. As per the conventional combines the use of fans, gravity and sieves, the remaining straw is separated from the grain. The clean grain then falls through adjustable sieves to be transferred to the grain tank.

Advantages

- High Capacity.

- Softer threshing of fragile grains.

- Ability to handle a wide range of crop types.

- Less moving parts than conventional.

Disadvantages

- Higher power requirements.

- Harder on straw and can pulverise.

Share Ag News Via